Research results

Welcome to the ValueBioMat research exhibition!

Here, some chosen research results are presented in form of research cases, posters and solution cards.

https://plasticseurope.org/changingplasticsforgood/the-plastics-transition/

Takeaways:

- Even in high-demand scenarios, the land required for raw materials only reached max 0.6% of global agricultural land.

- Secondary material inputs per source can remain relatively low also in high demand scenarios. For instance, in an all-of-the-above scenario (last row in table), 25% of materials would need to originate from each recycling source.

- As part of a broader sustainability transformation, land use by livestock could downscale to make space for raw materials production and more ecologically efficient (nutrition per ecological impact) foods.

Learn more about this research:

Research Poster:

Is it possible to reach a 25% biobased carbon share in plastics?

Challenge:

“What is the effect on land use for food production?”

“How does recycling affect the picture?”

“Is the target feasible when plastics demand keeps growing?”

Research Poster:

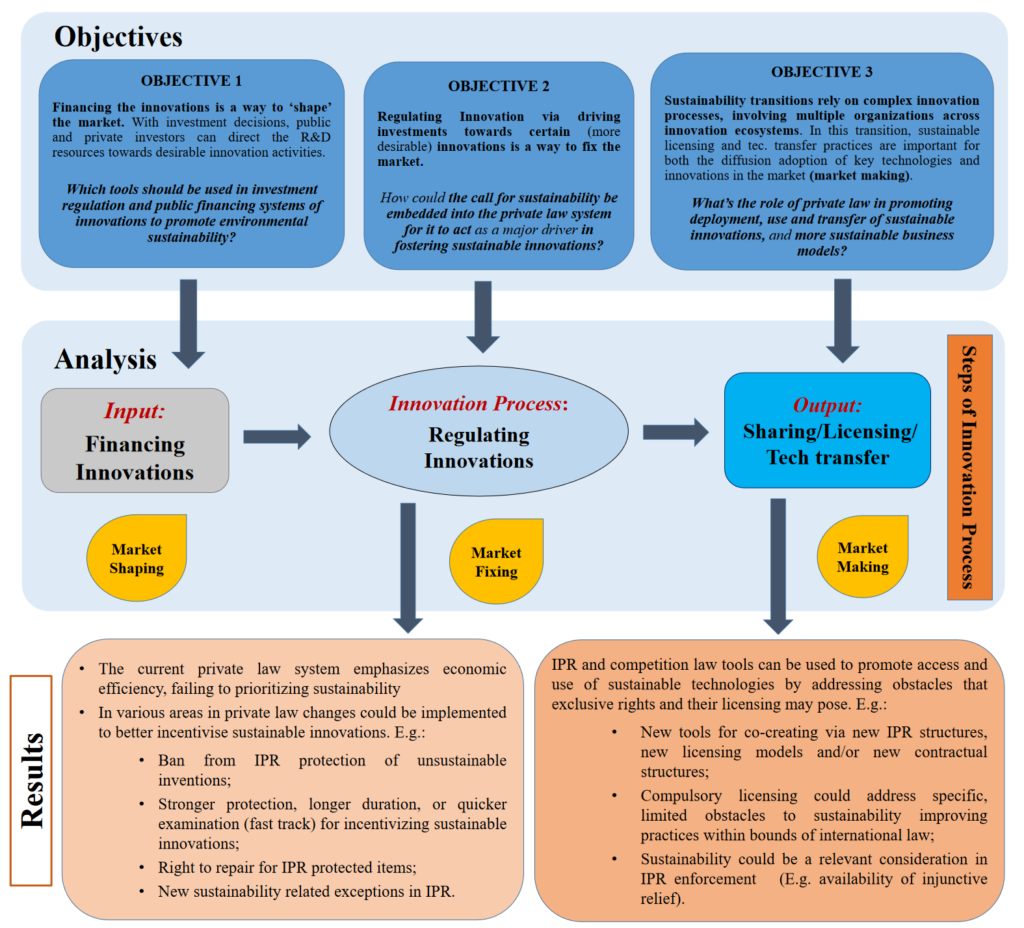

Sustainable Innovations & Practices

Learn more about this research:

Research Poster:

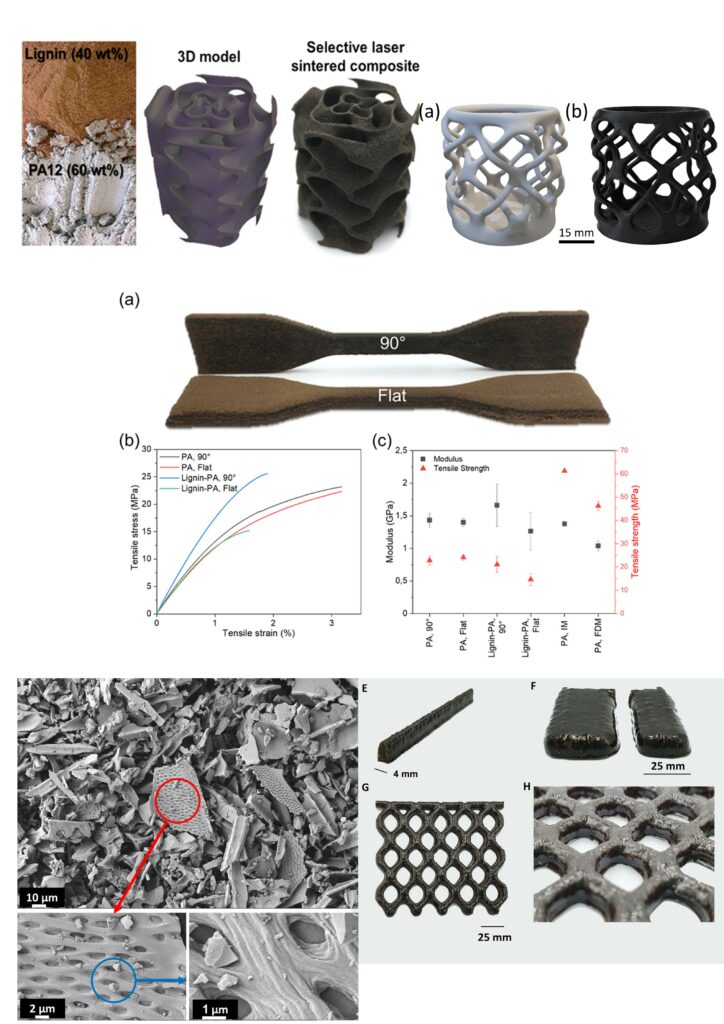

Transforming byproducts into high-value materials: composite utilization of lignin, sawdust,

and biochar

Challenge:

To investigate and demonstrate innovative and sustainable methods for converting lignin, sawdust, and biochar byproducts into valuable composite materials

Learn more about this research:

Research Poster:

Product Lifetime-Extending Interventions: Measuring Circular Economy Impact

Challenge:

Value retention of repair is unclear: who benefits, who loses out, what is the effect on the circular economy?

Results:

- We need to develop circular economy indicators focused on repairs

– Current circular economy indicators are focused on large loops, such as recycling.

– Existing indicators lack capability in identifying important aspects, such as repairability and required assets (service supply chain)

– Previous research puts too little emphasis repairs in comparison to refurbishments. - We need to design economic incentives for manufacturers, in addition to giving users the “right to repair”

Learn more about this research:

Results:

- Plastics with fossil-based raw materials have impact on:

– Chemical pollution – Novel entities

– Climate change

– Freshwater change - Bioplastics and biocomposites help to reduce those changes, but can increase issues related to land use

Learn more about this research:

Research Poster:

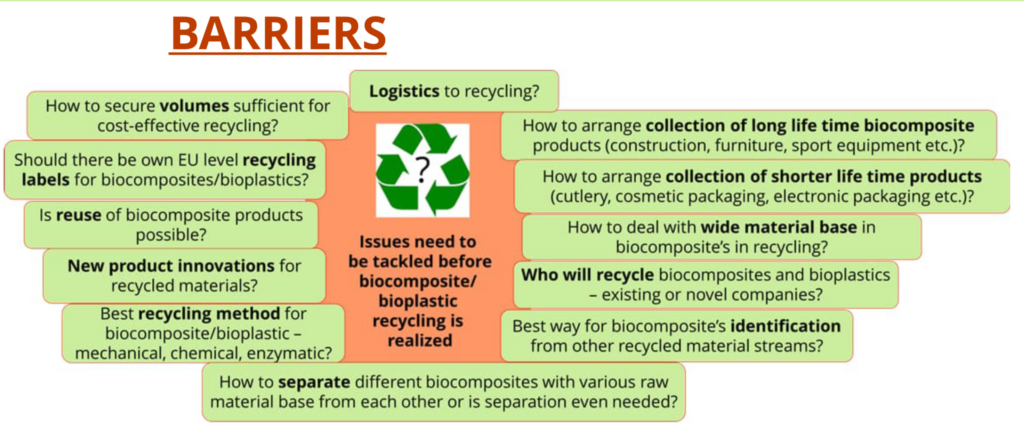

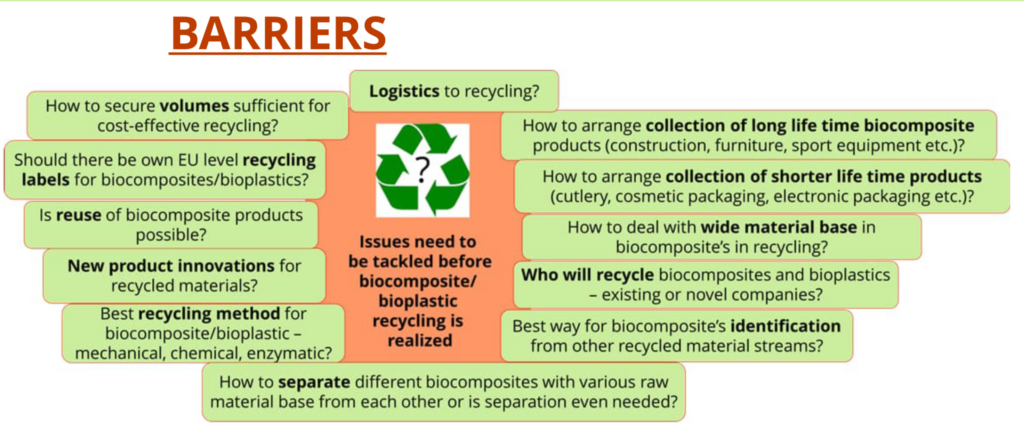

Exploring drivers and barriers of Biocomposites’ circularity

Challenge:

Exploring drivers and barriers of Biocomposites’ circularity

-> CIRCULAR ECONOMY IS NEEDED FOR ALL MATERIALS

Research Poster:

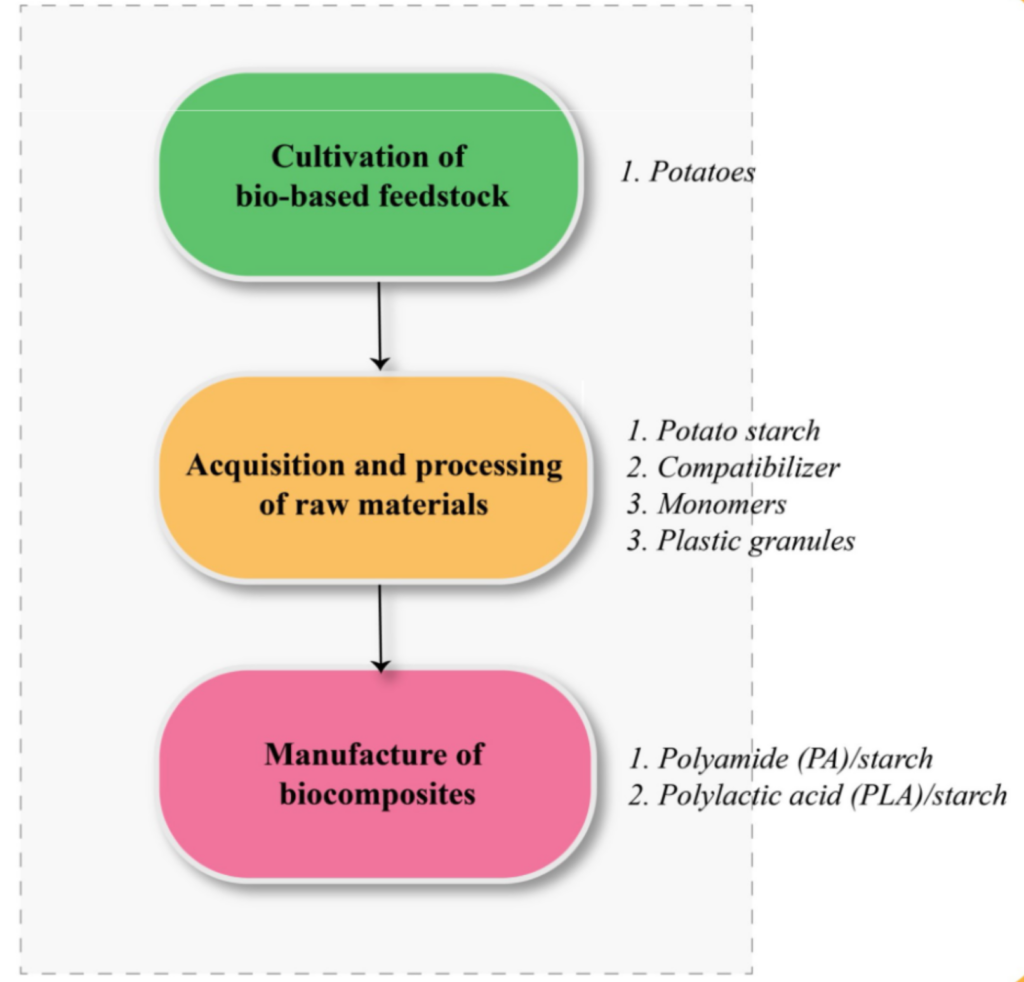

Exploring the Carbon Footprint of Biocomposites through Life Cycle Assessment

Challenge:

Accelerating climate change demands the development of more climate friendly plastics and biocomposites, so it is beneficial to quantify the impacts of plastics and biocomposites already at the early stages of development!

Results:

- Two cases polyamide (PA)/starch and polylactic acid (PLA)/starch were studied from cradle to gate.

- In both cases, monomers/PLA contributed the most to the carbon footprint.

Research Poster:

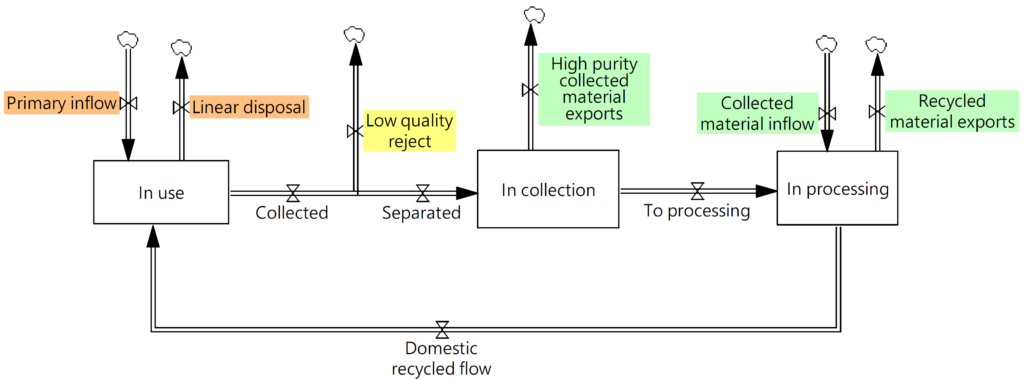

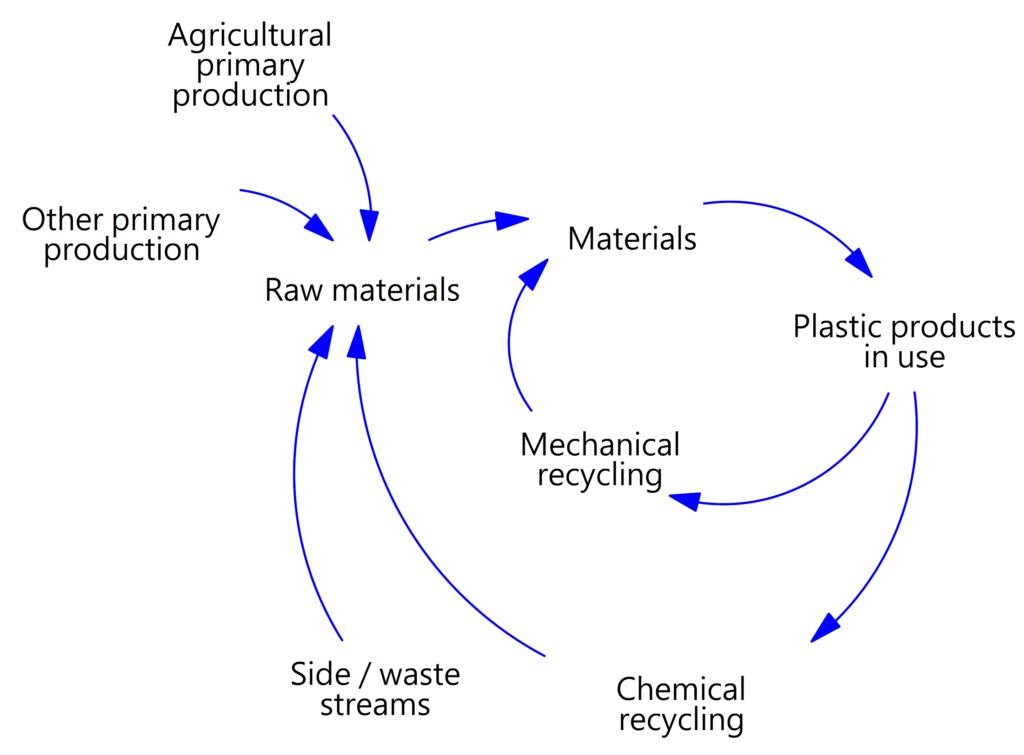

Simulation Modelling Plastics Circulation

Challenge:

What are high-impact intervention points for increasing circularity?

Solution:

- With simulation modelling we can test alternative assumptions at the macro level , while considering uncertainties

- We test different changes to this system, and observe how linear and circular flows change in the system.

Research Case:

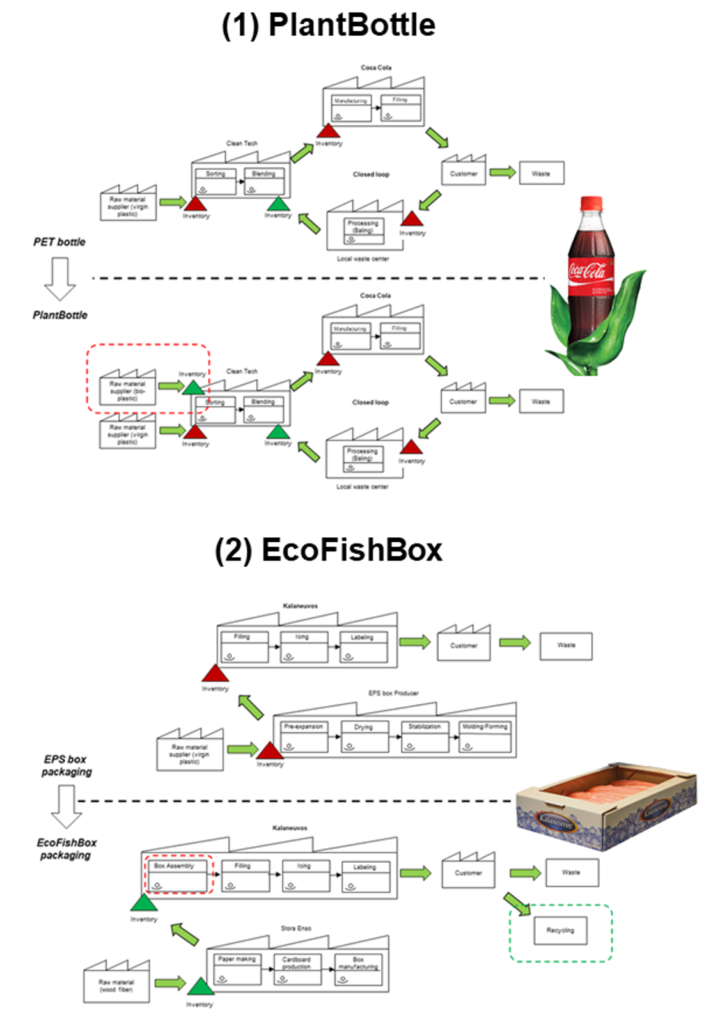

Impact of Bio-Based Packaging on Supply Chains

Author: Alireza Jaribion

Challenge:

What are the implications of bio-based packaging (BBP) on supply chain complexity, and how does the adoption of BBP within companies vary based on these implications?

Solution:

- We examined two BBP solutions—Coca Cola’s PlantBottle and Kalaneuvos EcoFishBox—as our case studies, selecting the end-product manufacturer’s perspective to analyze supply chain complexity and its implications for BBP adoption.

- Our findings reveal that BBP has the most significant influence on upstream and internal manufacturing complexities.

- Moreover, by paying specific attention not only to the material but also to the logistics, assembly, and recyclability of the new packages at the customer’s end, BBP implementation can decrease supply chain complexity to support BBP adoption.

- Our study also provides insights for managers to consider supply chain complexity in the design of sustainable packaging solutions, which can increase production efficiency and lower the cost of BBP, thus removing additional barriers from the adoption of sustainable packaging solutions.

Learn more about this research:

Research Case:

Authors: Laura Äkräs, Marjatta Vahvaselkä, Frans Silvenius, Jukka Seppälä, Hannu Ilvesniemi

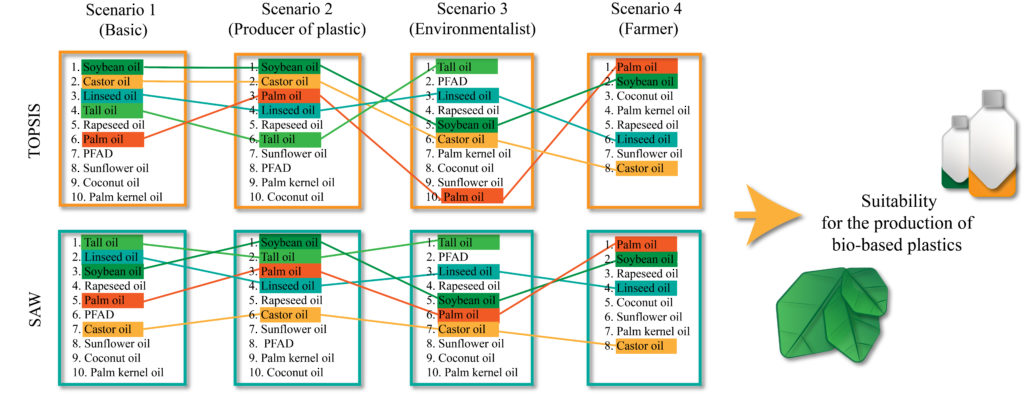

Challenge:

What is the performance, and therefore suitability, of the selected plant-based oils to produce bio-based plastics?

Solution

- A criteria-based Multi-Criteria Decision-Making (MCDM) framework consisting of two MCDM techniques, four scenarios with different weights of importance, and two datasets was constructed to evaluate the selected plant-based oils with a basis on their sustainability and technoeconomic characteristics

- The MCDM results were influenced by the dissimilar algorithm of Technique for Order Preference and Similarity to Ideal Solution (TOPSIS) and Simple Additive Weighting (SAW) techniques together with the developed MCDM framework

- Tall, linseed, soybean, and palm oil showed the most suitable and palm kernel, coconut, and sunflower oil the least suitable performance with their feature trade-offs to produce bio-based plastics

Learn more about this research:

Research Case:

Synthesis of bio-based and CO2 capturing polymers for 3D printing

Author: Hossein Baniasadi

Challenge:

Sustainable polymer solutions are often compromises of materials characteristics versus environmental benefits. What bio-based polymers and composites can compete with or outperform fossil-based polymers while being carbon capturing?

Solution:

- We have developed a family of bio-based polyamides (PA) with mechanical and thermal properties comparable to fossil-based polymers.

- Moreover, high-performance composites have been created utilizing chemical compatibilization, through surface modification of the bio-based fillers.

Research Case:

Forecasting Legal and Ethical Paths for Minimizing Extractivism through 3D Printing Technologies

Authors: Research Team

Challenge:

Many products that we regularly consume are based on damaging and unsustainable ‘extractivist’ practices. (Info on Extractivism)

The aim of this research work is to identify alternative perspectives on the future of extractivism and the associated production system, as well as to understand how 3D printing when supported by law and policy could help minimize it.

Design credit: Amna Qureshi, Doctoral Candidate, Faculty of Art and Design, University of Lapland

Solution:

- In order to achieve this, we follow a three-phased approach utilising scenarios – linking together impacting factors from wide-ranging fields into narratives on how the future will develop itself and what impact it will have on the social-ecological systems. (Info on Methodology)

- Initial outcome includes four scenarios that narrate alternative perspectives on extractivism in the year 2032, the associated production system with its enablers, and the consumer mindset and governmental actions that led to the respective future states. These scenarios help at challenging the prevailing mind-set of consumers and producers and help various actors with options to react to the change quickly.

- The final outcome will be a journal article (manuscript is currently under preperation), and will include an implementation roadmap that could potentially aid the stakeholders in prioritizing goals for moving away from extractivism

Learn more about this research:

Research Case:

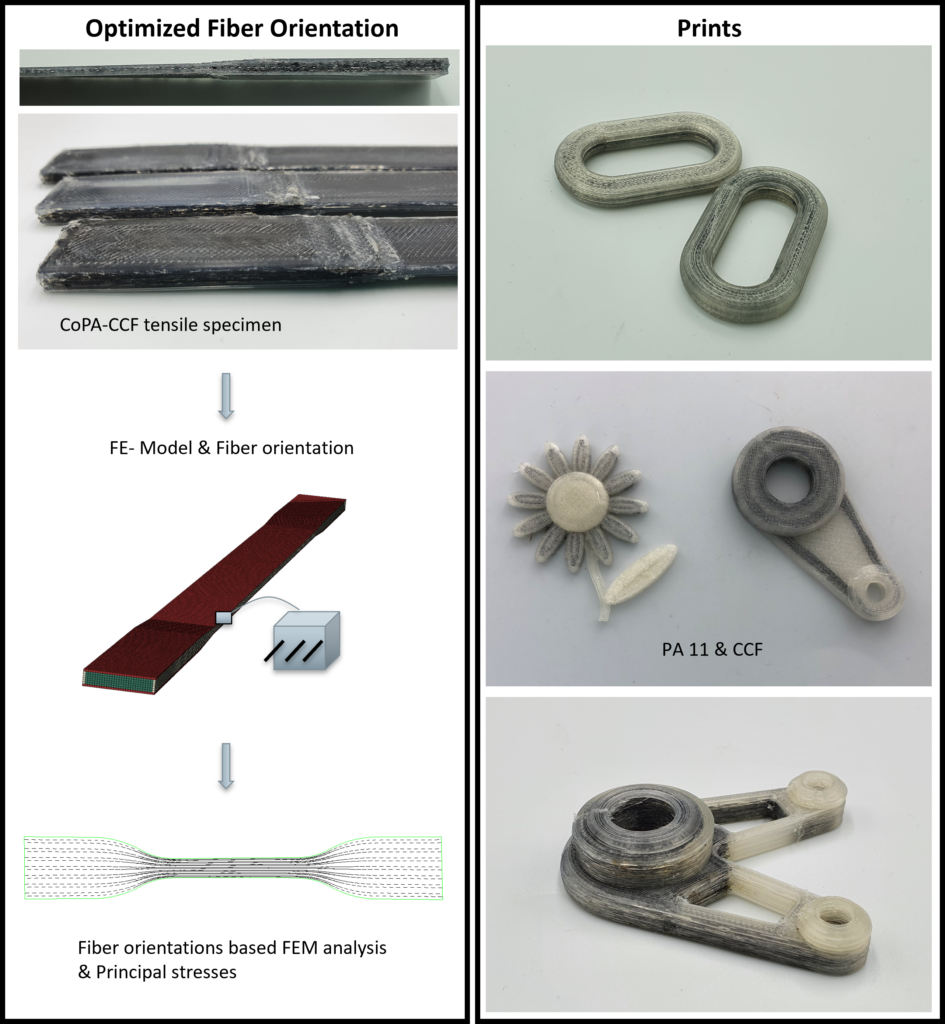

Continuous-carbon-fiber-reinforced 3D printing of polyamides and print path optimization

Authors: Siddharth Jayaprakash, Humberto Almeida, Kari Kolari, Hossein Baniasadi, Tuukka Verho, Niklas Kretzschmar, Kirsi Kukko, Kirsi Immonen, Sini Metsä-Kortelainen, Jukka Seppälä, and Jouni Partanen

Challenge:

Novel approach for reinforcing polymers and optimizing end-use parts with long continuous fibers, thereby improving the overall strength.

Solution:

- Prototypes are made with commercially available copolyamide, and a bio-based PA11 filament made at VTT (from commercial material).

- Tensile tests are conducted for CCF-reinforced specimen 3D printed with commercial copolyamide filament.

- This work is supported by modeling and simulation with a goal to find the best fiber placement configurations.

- Numerical simulation is an important part in the optimisation and the development of fibre reinforced specimen.

- A procedure to generate FE-mesh with fibre information has been proposed and programmed.

- Material analysis has been carried out for the virgin material and the 3D printed specimen.

- Future work is aimed at 3D printing optimized designs (optimized print path from the simulation work) utilizing bio-based polyamides.

Research Case:

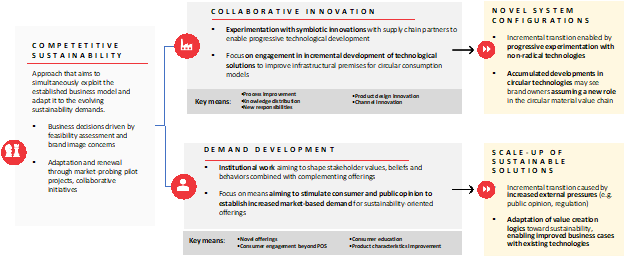

Socio-technical transition to a sustainable plastics economy

Author: Pyry Päivölä and Jaakko Siltaloppi

Challenge:

How can brand owners contribute to a system-level transition toward sustainable plastics?

Solution:

- Integration of sustainability demands in existing business models: Leveraging sustainable plastics for competitive advantage allows brand owners to respond to growing demand for sustainable materials while continuing to exploit established business models.

- Pursuit of parallel development avenues: Collaborative innovation with value chain partners organized through pilot projects allows brand owners to experiment with novel materials and supply chain solutions in small scale. Involvement in infrastructure development for plastics circulation through incremental development of product designs, material supply chains, technologies for recycling.

- Contribution to system-level transition through incremental changes: a) Progressive experimentation with novel solutions, when engaging other players in the material value chain, can accumulate into new value chain arrangements that support efficient and effective material circulation. Impacts the plastics value chain by creating new system-level solutions. b) Growing demands for sustainable materials and packaging drives gradual adaptation in the business logic of brand owners, reinforces the business case for the use of sustainable materials. Impacts the plastics value chain by increasing the scope of sustainability-oriented actions.

Learn more about this research:

Solution:

- Small link designs are 3D printed with PETG reinforced with CCF as infill, utilizing Anisoprint Composer A4.

- Links were also 3D printed with solid PETG, without any reinforcement, for strength comparison.

- Lifting demo was carried out utilizing an in-house gantry crane and a wooden pallet attached to the CCF-reinforced link.

- Both the reinforced and solid PETG links were pulled in a universal testing machine – the reinforced link was able to withstand twice as much load before fiber breakage, compared to the solid plastic link that experienced a brittle fracture.

- Small link designs are 3D printed with PETG reinforced with CCF as infill, utilizing Anisoprint Composer A4.

- Links were also 3D printed with solid PETG, without any reinforcement, for strength comparison.

- Lifting demo was carried out utilizing an in-house gantry crane and a wooden pallet attached to the CCF-reinforced link.

- Both the reinforced and solid PETG links were pulled in a universal testing machine – the reinforced link was able to withstand twice as much load before fiber breakage, compared to the solid plastic link that experienced a brittle fracture.

Research Case:

Continuous-carbon-fiber-reinforced 3D printing of a small link design and its lifting demo

Authors: Kirsi Kukko and Siddharth Jayaprakash

Challenge:

To demonstrate a novel approach for reinforcing polymers with long continuous fibers, thereby improving the overall strength. We aimed to visually demonstrate the improved load-carrying capacity of a ring design 3D printed with PETG as the matrix polymer and continuous-carbon-fiber (CCF) as the reinforcement.

Learn more about this research:

Research Case:

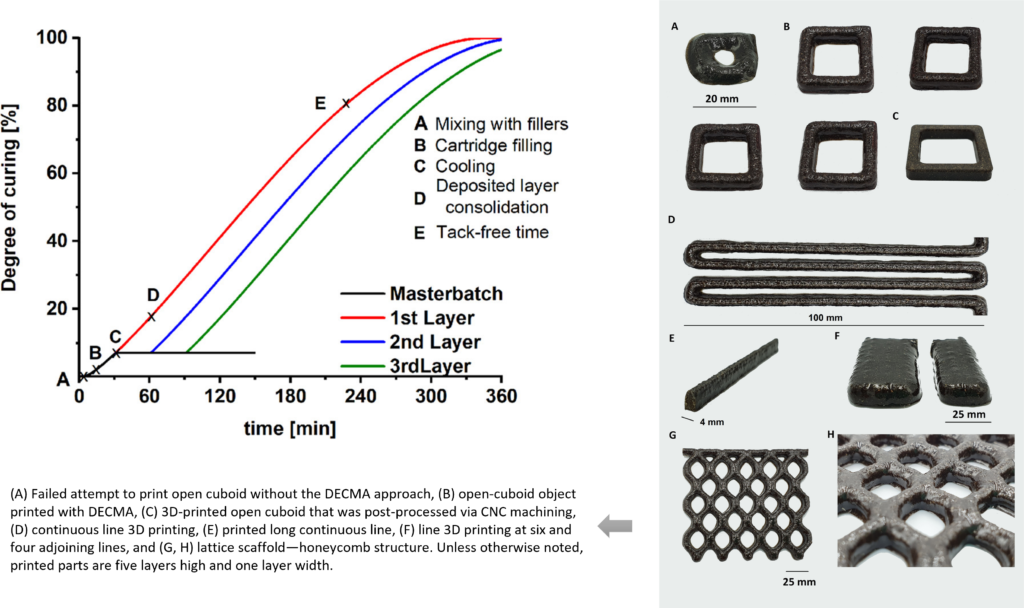

3D-Printed Thermoset Biocomposites Based on Forest Residues by Delayed Extrusion of Cold Masterbatch (DECMA)

Author: Jon Trifol, Siddharth Jayaprakash, Hossein Baniasadi, Rubina Ajdary, Niklas Kretzschmar, Orlando Rojas, Jouni Partanen, Jukka Seppälä

Challenge:

The objective of this work is to revalorize lignin and sawdust via 3D printing using bioepoxy as a carrier. However just the incorporation of these particles within the polymer matrix does not improve the rheological properties of the bioepoxy enough to be 3D printable. Keeping this in mind, we sought to shift the burden in 3D printing from materials to a processing method, so otherwise unprintable materials can be printed.

Solution:

- We propose a new 3D-printing processing technique termed Delayed Extrusion of Cold Masterbatch (DECMA), which enables the 3D printing of thermoset biocomposites.

- A bioepoxy-based ink containing a 20% of sawdust and 15% of lignin (with a total bio-based content of 58–71%) was developed.

- The incorporation of lignin and sawdust increased the starting viscosity of the mixture from 103 to 105 mPa·s and provided shear-thinning behavior without affecting the curing kinetic.

- In DECMA, the degree of curing of the ink is controlled via time/temperature conditions. The ink is cooled down to stop the reaction and the 3D printing is started.

- It was found that the ink was not printable using the direct printing approach, but using DECMA, several parts (i.e., cuboids, adjoining lines, parallel lines, and honeycomb) were successfully 3D printed.

- Additionally, 3D-printed parts could easily be machined, thereby showcasing potential for hybrid manufacturing.

Learn more about this research:

Results:

- Plastics with fossil-based raw materials have impact on:

– Chemical pollution – Novel entities

– Climate change

– Freshwater change - Bioplastics and biocomposites help to reduce those changes, but can increase issues related to land use

Learn more about this research:

Research Poster:

Exploring drivers and barriers of Biocomposites’ circularity

Challenge:

Exploring drivers and barriers of Biocomposites’ circularity

-> CIRCULAR ECONOMY IS NEEDED FOR ALL MATERIALS