Authors: Jukka Seppälä & Arun Teotia (Aalto University) and Katri Valkokari (VTT)

European Commission has published a policy framework for biobased, biodegradable and compostable plastics on 30.11.2022. Here the authors aim to share our elaboration on essential key statements and conclusions related to the EU framework.

COM(2022) 682 final (1)

In Europe and internationally, biobased, biodegradable and compostable plastics are widely perceived as more environmentally friendly than conventional plastics. Thus, there is increasing scientific evidence that a number of conditions have to be met to ensure that the production and use of these plastics result in overall positive environmental outcomes, which do not increase problems of plastic pollution, climate change, land and water use and biodiversity loss. The biobased plastics have their own sustainability challenges and trade-offs that should be well understood and duly taken into account in order to not make problems of plastic pollution, climate change and biodiversity loss even worse. Furthermore, a renewable carbon feedstock is an alternative to fossil carbon and associated advantages. Utilization of organic waste and by-products will offer a feasible solution to avoid “greenwashing” and avoid misleading the consumers by using generic claims on plastic products such as “bioplastics” and “biobased”.

Defining biobased plastics

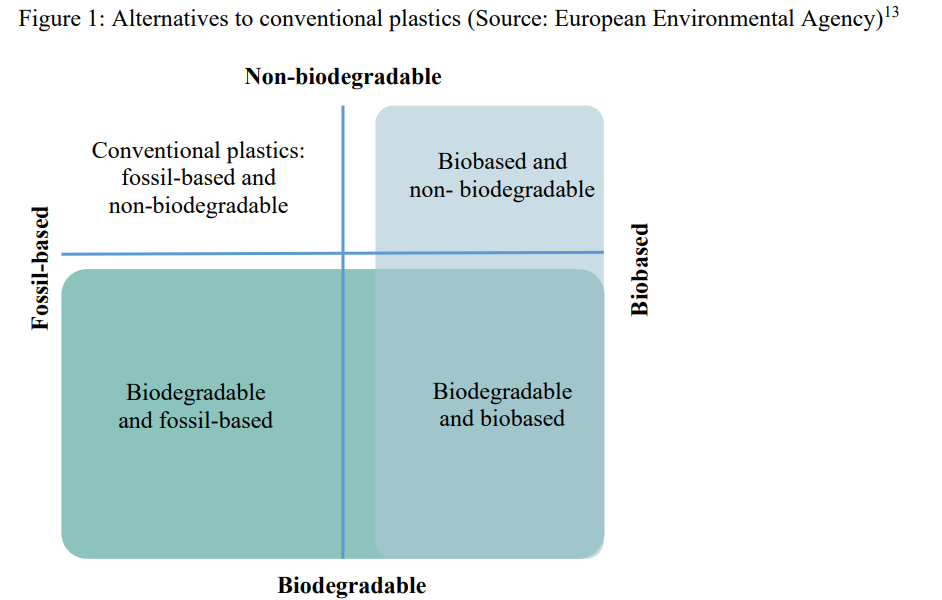

The aim of European policy framework for biobased, biodegradable and compostable plastics is to provide better understanding of the challenges and benefits that stem from their use. Here the starting point is the understanding the different concepts related to the conventional and biobased plastics, as presented at the figure 1.

Enhancing feedstock sustainability

Currently, the amount of biobased plastics produced is still marginal (< 1% of total plastic production). Even though the objective for reaching climate neutrality is set to 20% (2) of the carbon used in chemical and plastic products should be from sustainable non-fossil resources. In most cases, the production of biomass for biobased plastics requires the use of natural resources such as land and water and the use of chemicals such as fertilisers and pesticides. It is important to consider, when use of biobased feedstock results in unpretentious environmental benefits, going beyond decrease in using fossil resource. Only biobased plastic products with sufficiently long usage lifetime and when they are not incinerated at end of life, they can provide beneficial carbon storage effects. Therefore, it is crucial to consider the sustainability and whole lifecycle of feedstock, which is one of the research topics at ValueBioMat project. http://www.valuebiomat.fi

Developing novel innovative materials

Material research and development is still needed to deepen our knowledge on characteristics of bioplastics and their most suitable application areas. On the other hand, many new plastic materials are emerging on the market, which brings confusion to the consumers. There is currently no mandatory minimum biobased content nor agreed certification scheme or label for a plastic product to be labelled as biobased. Further, there is a need to ensure that labelling a product as “biodegradable” or “compostable” do not mislead consumers and does not encourage them to dispose-off it in a plastic littering way. In case the timescale for biodegradation is short enough, that they are fully degraded in the receiving environment, the biodegradation is indeed an important characteristic to avoid accumulation on the receiving environment. Overall, the labelling with different green, eco, bio documentations is building more chaos than guidance has been noted also through the studies of ValueBioMat project.

Outlining impacts of biodegradable plastics

While using the biodegradable plastics the concept of 3R’s (reduce, reuse and recycle) cannot be overlooked. One objective should be to minimize waste generation using the 3R policy as much as possible. Through this way, materials of all feedstocks, including the biobased feedstocks are kept in the loop for as long as possible reducing waste generation. Another objective is to achieve carbon neutrality by ensuring feedstock sustainability and life-cycle assessment. Further, use of biodegradable plastics should minimize plastics waste accumulation in an open-environment (minimizing environmental pollution) thus minimizing associated environmental hazards. However, this should not be taken as an excuse to “littering” problem. For, this proper waste management systems should be utilized for collection and segregation of biodegradable plastics at the end of their lifecycle. This will minimize environmental plastic pollution, cross contamination and mix-up in plastic recycle feedstocks.

The EU policy paper discusses biodegradation of materials as follows: the materials (plastics) designed to decompose at the end of their life by the conversion of all the organic matter into carbon dioxide, water, minerals, and organic biomass. In addition to the characteristics of the materials, suitable conditions in the receiving environment and sufficient time are necessary to prevent assimilation of the materials in the receiving environment. Thus, plastic biodegradation must be considered not only as a materials property, but as a system property, where both the material related, and environment related factors are equally important (3). Further, it is increasingly subject to policy measures designed to ensure that biodegradable plastics should bring environmental benefits and that consumers are not given the impression that biodegradable plastics can be littered. For this appropriate labelling and customer awareness measures are required. The claims on biodegradation should be minimized/not made on litter prone products (coffee cups, ready to eat food packaging etc.) as mentioned in Single-Use Plastics Directive. Using biobased or biodegradable materials as substitutes, should not be considered as a solution for inappropriate waste management or littering. The effect of these materials and additives on receiving environment should be thoroughly studied before approval and certification.

Continued actions needed; ValueBioMat project as a one tool of implementation

To sum up, we have identified key features and challenges to be met in striving towards more sustainable solutions based on the guidelines of EU policy framework for biobased, biodegradable and compostable plastics:

- Non-fossil alternative substitutes for fossil raw-materials needs to be continued and intensified

- Opportunities of disruptive novel technologies need to be considered carefully; circular economy, biobased solutions and Power-to-X based materials production

- Science based research and knowledge on the life cycle analysis over the whole value chain and products’ impacts should be intensified

- The results of thus generated LCA-results should be solid basis in planning and regulating the uses of materials

- Associated standards and labelling need to be developed, as well as regulation and incentives as tools

Strategic Research Council funded ValueBioMat project (4) is one important tool to reach these goals. Our ValueBiomat consortium is building science-based understanding that enhance the transition towards sustainable use of plastics. There, biobased, biodegradable and compostable plastics can bring advantages over conventional ones if designed for circularity, produced safely and from sustainably sourced feedstock.

(1) https://environment.ec.europa.eu/topics/plastics/biobased-biodegradable-and-compostable-plastics_en

(2) Current level is 10%. The part used to make plastics is 1 to 2%.

(3) https://www.sapea.info/wp-content/uploads/bop-report.pdf