The “Bio-oils-based polymeric composites – Value chain from synthesis to additive manufacturing (ValueBioMat[1])” project aims to provide top-tier scientific results, combined with practical solutions for how to move from the current mainstream fossil petro-chemistry-based polymeric materials to more sustainable, renewable and carbon-binding ones. One of the major global challenges we currently face in materials science relates to the transformation from a fossil petro-chemistry based polymeric materials to sustainable, renewable and carbon-binding ones.

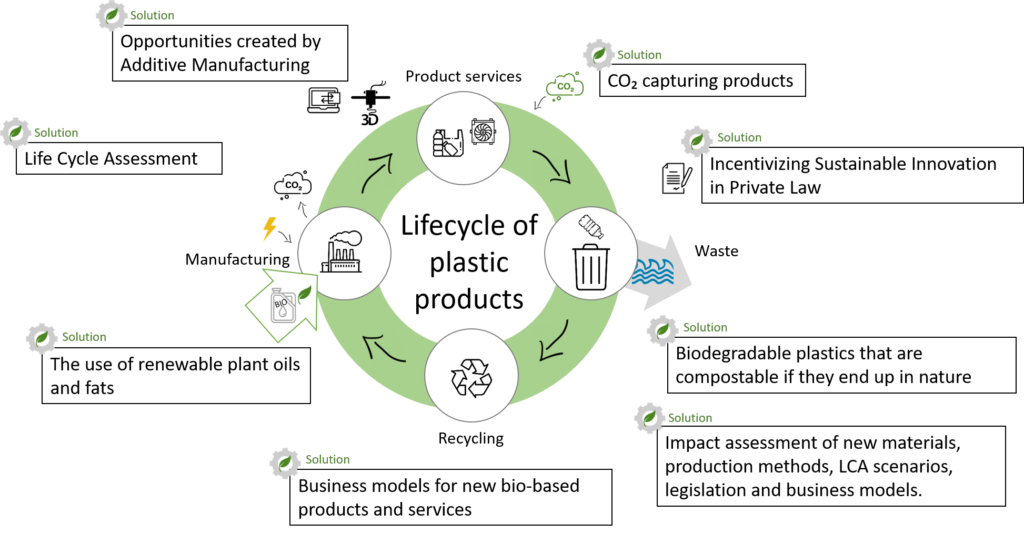

ValueBioMat presents a ground-breaking paradigm change, and provides the knowledge needed to foster the transition towards producing polymers fully based on renewable plant oils and fats. Figure 1 summarizes the solutions for a sustainable future utilizing bioeconomy feedstocks in polymer composites, digital manufacturing and the circular economy.

Figure 1. Eight elements for solving the global plastic challenge

ValueBioMat will, for instance deliver pioneering results for the production of bio-composites based on novel long-chain polyamides. In addition, the project will integrate developments on these novel bio-based and CO2-capturing composite materials, with emerging digital and additive manufacturing (AM) technology. As a novel breakthrough in AM, reinforced composites manufacturing will be investigated. Moreover, ValueBioMat will develop novel suitable business models and address the changes needed in the legal framework in order to support a smooth transition towards distributed (i.e. non-centralized, local) manufacturing of bio-based polymeric products.

The consortium of ValueBioMat brings together the multidisciplinary teams of four of Finland’s top research institutes: Aalto, LUKE, University of Lapland and VTT. Consortium director, Jukka Seppälä, Aalto University/School of Chemical Engineering, highlights:

Our research group has already discovered a proven pathway from bio-oils to high-performance polyamides.

Together with Aalto University School of Engineering the aim is to develop suitable AM technologies for such novel composites. Professor Jouni Partanen, whose group is specialized in advanced production technologies pointed out:

Different AM technologies will bring new possibilities to re-configure spare parts supply chains. Biopolymers will be applied later to other more widely used production technologies after we have learned the lessons from AM

Aalto School of Science operations management team, led by Professor Jan Holmström, is exploring feasible business model designs to shift highly centralized petro-chemical supply chains towards bio-based local manufacturing and closed-loop value creation. Furthermore, as Rosa Ballardini, Associate Professor at University of Lapland/Faculty of Law, notes:

There is a significant research gap in private areas of law related to fostering sustainability values and sustainable innovations. For instance, in the current Intellectual Property Rights (IPR), competition and contract law regimes may actually hinder, rather than support, the transformation towards bio-based plastic value chains and the emergence of new, more sustainable innovation ecosystems”.

Hannu Ilvesniemi, Research Professor with Natural Resources Institute Finland, continues pointing out the need for system level approaches:

Our competences in holistic ways of analysing the properties and sustainability of versatile bio-based raw materials with Life Cycle Assessment type methods complements the multidisciplinary consortium”.

VTT Technical Research Centre of Finland is working on the activities of stakeholder collaboration of ValueBioMat consortium. Principal Scientist Peter Ylen emphasizes the meaning of active collaboration:

Stakeholder collaboration is a key for systemic transformation, as paradigm change is needed on several levels from us as individuals to society as whole”

Finland provides an ideal context for this research, especially due to the fact that the country is at the forefront of scientific research in all the relevant disciplines, as well as in the wide industrial production of refined bio-based oils and fats that can be used for the production of bio-polymers. Some forerunner companies in sustainable technologies and materials are project partners committed to collaboration. Moreover, we expect also considerable new investments in this field, such as new companies originating from the new business models and developed incentives structures. Overall, our holistic approach provides what is needed in order for the concepts developed in ValueBioMat to be of a disruptive nature and to have great socio-economic impacts globally.

xxxxxxxxxxxxxxxxxxxxxxxxx

[1] ValueBioMat is a multidisciplinary project funded by the Strategic Research Council (SRC) at the Academy of Finland (2019–2025). The project is part of the Innovative Materials and Services to Promote Resource Wisdom and Sustainable Development (IMPRES) programme. In the January 2020 newsletter of Strategic Research Council the focus was on sustainable development and ValueBiomat was presented together with other IMPRES projects. Link to the newsletter.