Author: Teemu Mikola

In recent years, the environmental problems related to plastic materials have been gaining increasing attention. Although plastic materials deliver many benefits, such as durability, light weight, and low cost, they depend on fossil resources and create emissions and harmful waste in many stages of their value chain. To address these challenges, the plastic industry has begun a transition towards circular economy as well as bio-based alternative feedstocks.

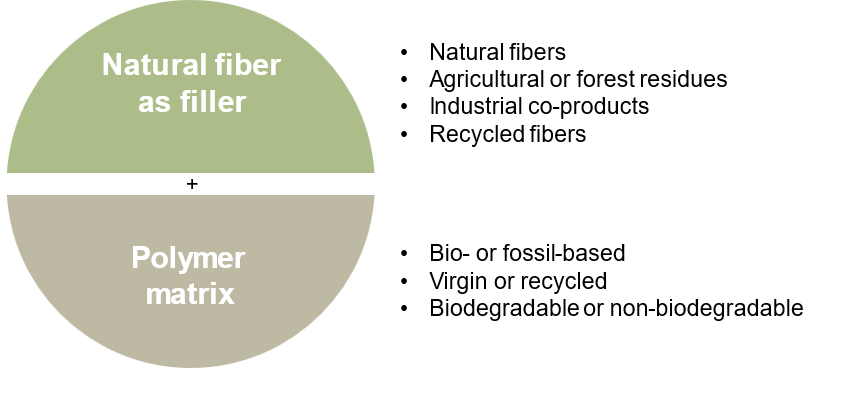

Within this development, some material producers have introduced so-called biocomposite materials (Figure 1) to the market as a sustainable alternative to fossil-based plastics. What makes these materials interesting is their potential to utilize side-streams from other industries, including forestry and agriculture, as a bio-based filler material in plastics, thus substituting fossil-based material.

Although biocomposites have been investigated by material technology research, and have seen some commercial traction, their potential has not been vastly researched from a holistic and practice-oriented viewpoint. In my master’s thesis for the ValueBioMat research project and the Department of Industrial Engineering and Management at Aalto University, I investigated the role of biocomposite materials in the wider transition of plastics towards environmental sustainability and circular economy. I examined research literature and conducted a case-study of the Finnish plastic sector with 19 expert interviews from different organizations in the plastic value chain.

Biocomposites can solve some problems of bio-based plastics

Although representing still a marginal share of plastic production, plastics made from bio-based feedstocks have showcased some challenges. Feedstocks often originate from plants that could alternatively be used for food production, and growing these crops on a large scale would require tremendous amounts of scarce arable land and fresh water. Moreover, the high prices of bio-based plastics make their competitiveness poor against fossil-based plastics.

In biocomposites, on the other hand, bio-based content is added to the material by blending natural fibers into the plastic, reaching even 50% or more of the resulting material. This seems attractive since available and often cheap side-products from other industries can be utilized as a filler. Thus, biocomposites could potentially decrease the costs of introducing bio-based content to plastics without links to food production or increasing land and water use.

Based on the study, the practical perspective is not as straightforward. As anticipated, most commercial biocomposites are produced by valorizing different side-stream resources, and thus can mitigate some effects. However, although these resources are cheap, the different production processes are more complex and require more energy, which makes them still a costly alternative. This limits their attractiveness as a material choice for products.

Recycling is not designed to process biocomposites

Transitioning to a circular economy, mostly developing recycling, was seen as the most important effort to mitigate the environmental effects of plastics by the interviewed industry representatives. However, recycling rates today are still very limited: around 30% in packaging, which represents 44% of plastic consumption. Outside packaging applications recycling is yet virtually non-existent.

Nevertheless, biocomposites were mostly criticized because they are very difficult to recycle in the practical recycling infrastructure. Recycling operates only for mainstream plastics with high volumes, and anything more complex ends up rejected from recycling. However, the criticism mostly relates to the practical setup of recycling, and biocomposites can in theory be recycled if the setup adopts different approaches.

In addition, biocomposites can offer only limited changes towards less harmful ways of disposing compared to fossil-based plastics. Biodegradability is not considered as a good alternative for any plastics. Researchers have also proposed approaches to convert plastics into other carbon products, such as biochar via pyrolysis, and store the carbon instead of releasing it to the atmosphere. However, biocomposites impact the attractiveness of these approaches only limitedly.

The way forward for biocomposite solutions

Since plastic recycling is today still limited, biocomposites can have sustainability benefits under certain circumstances. Biocomposites could especially be a sustainable alternative in segments that are currently not in the scope of recycling, namely most non-packaging applications, such as consumer products and construction. Given these constraints, as well as some technical limitations that biocomposites have, their feasibility should be evaluated case-by-case. In the longer term, however, as recycling is expected to expand, other approaches than biocomposites may prove more beneficial, if they compromise recycling less.

Interested? The thesis can be found here