Authors: Jaakko Siltaloppi/ Aalto and Markus Jähi & Katri Valkokari/VTT

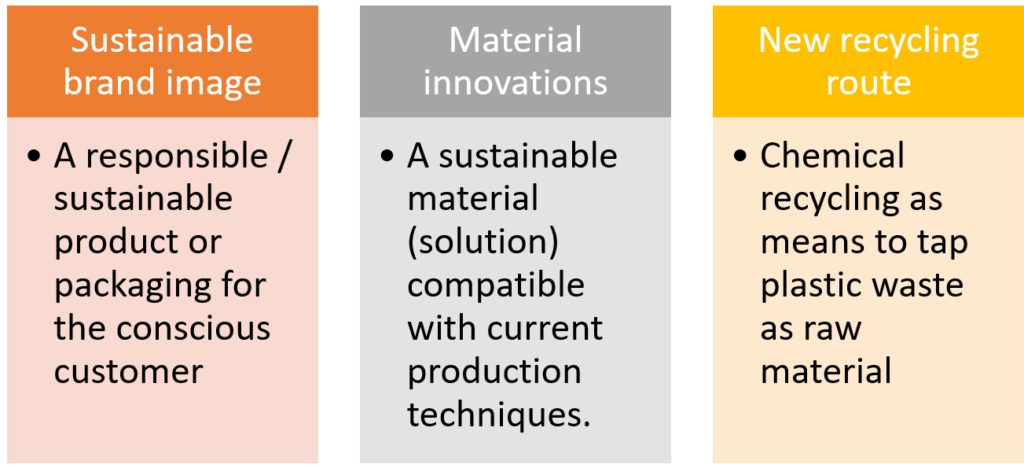

Transitioning to ‘renewable’, bio-based and recycled plastics is not an easy task – or something one could do alone. Therefore, it is important to find new ways to engage a variety of stakeholders in a shared problem-solving process. Based on our research work at ValueBioMat project we had identified three potential avenues for the transition of the plastics ecosystems (Figure 1). Together with key stakeholders, i.e., our advisory board members, we discussed the strengths and weaknesses of these three emerging business models.

Figure 1. Value propositions of three emerging business models

Building sustainable brand image through ‘bioplastics’

The development path of this business model is connected with the current everyday discussion on plastics. With increasing demand for sustainability among consumers, manufacturers and brands have the ability to boost their brand image by using renewable materials in their products and/or packaging. This helps the brands to dissociate from the ongoing public discussion, in which plastics are seen as an ‘evil’ material and their superior characteristics or essential role in modern life are often forgotten. Regulation on European level is seen as important driver for this pathway. For example, it was pointed out:

“one fundamental question even is: what is plastics?”.

Many challenges also remain for this business model. It was noted that bio-feedstock offer a very limited raw material source. Therefore, it is important to consider to which applications bio-based plastics or composites are best suited and give the highest impact. For instance, in some applications the properties of the fossil-based materials exceed the requirements. That could be one opportunity for recycled plastics that often suffer from slightly inferior material properties.

Material innovations as “drop-in” solutions

Various innovations with bio-based materials are currently emerging as alternatives to fossil-based virgin plastics. Regarding material innovations, there is a need to understand whether a totally new infrastructure in manufacturing and recycling is required, or if the existing infrastructure can easily be adapted to the new materials? The overall added value of the innovative material will play a crucial role. In addition to the environmental impact, the benefits for the whole value chain, including polymer producers as well as plastic product manufacturers and consumers should be considered. For instance, we should try to find new technologies to produce conventional monomers from waste materials and renewables in order to enhance resource sufficiency. Thus, it was emphasized that sustainability of the solutions can be more difficult to demonstrate compared to the first model and/or existing solutions. In order to ensure sustainability;

“the competitiveness of innovative materials should be considered based on complete Life Cycle Assessment (LCA).”

Systemic change through a new recycling route

There are several parallel recycling routes ranging from the re-use of materials to mechanical, chemical and biological recycling. Chemical recycling in particular is emerging as a potential solution to the quality issues associated with plastics recycling. Often the collection and separation of various plastics in different streams is a focal problem. In addition, many plastics, even bio-plastics, contain a high amount of fillers and additives, which need to be taken care within the recycling process. How to make this a sustainable, profitable business? When will this be a new stage in the value chain? Many participant highlighted that due to the active discussion on the plastic problem, the consumer willingness is already there. So, according to the comments the question remains:

“Do we lack technologies, incentives or business models for the different recycling routes? “

To sum up, any of these identified business models cannot solve the plastics problem alone, but have the potential of providing partial solutions to the plastics problem. And they all require a variety of changes within different levels of the current plastics ecosystem from consumer behavior to regulations. In the ValueBioMat project, we aim to solve these systemic challenges with multidisciplinary research consortium as well as active collaboration with our stakeholders.

Check our informative video for more information and let us know, if you are interested to join the crew!