Authors: Esko Hakanena, Jan Holmströma, Teemu Mikolaa, Kirsi Immonenb, Jukka Niskanenc, Hannu Ilvesniemid, Corinna Casie, Kirsi Kukkof, Jouni Partanenf

Plastics are often portrayed as a problem when tackling climate change. Plastic products made from fossil raw materials also deplete non-renewable resources. Moreover, plastics are commonly incinerated at the end of their life, to avoid microplastics and plastic waste polluting the oceans, releasing carbon dioxide into the atmosphere.

However, researchers in the ValueBioMat project propose a solution that contradicts plastics’ common reputation as an environmental burden: what if the plastics industry could be transformed into a global carbon sink system? Could plastics be transformed into a solution for combating climate change?

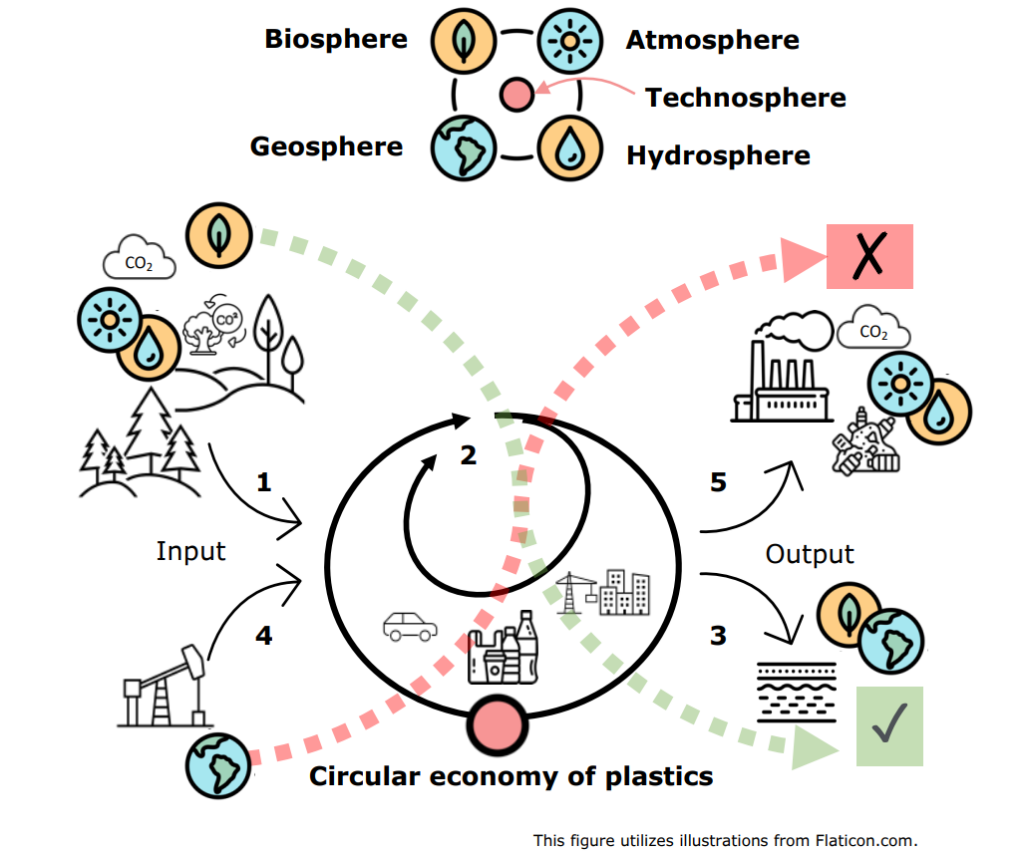

The ValueBioMat research project’s carbon transfer model (see original Finnish version here) builds on this perspective. It envisions a scenario where, with the right solutions, the plastic industry could be converted into a carbon sink. This model, which acknowledges the circulation of carbon in natural and human-made systems, demonstrates the potential for carbon to be bound to the atmosphere, water cycle, soil, plants and animals, or human-made products (often referred to as the “technosphere”).

Figure: The carbon transfer model illustrates the role of inputs and outputs of carbon in the circular economy of plastics

The model highlights the possibilities of bio-based plastics replacing fossil ingredients. The production of bio-based plastics would take advantage of the carbon sequestration ability of growing biomass, such as wood or crops. Carbon would first be bound to the plants through photosynthesis (storing carbon from the atmosphere to plants and soil) and then transferred to the plastic products during manufacturing (from plants to technosphere). In a circular economy, long product life cycles and the use of recycled materials are imperative. The longer the carbon remains bound in products, the longer it stays out of the atmosphere.

However, the actual carbon sink would only emerge at the end of the plastic product’s life cycle. The goal would be to “refossilize” plastic waste, returning it close to its original fossil-based form. The refossilized material could then be safely and permanently buried in the soil (from technosphere to soil). This way, plastic products would become a solution in fighting climate change by sequestering carbon out of the atmosphere.

Pathway to the Future

A holistic transformation of the plastic industry will be demanding. To begin, the availability and production of bio-based raw materials must be ensured sustainably without sacrificing land from food production or other more valuable uses, and without cutting down or reducing forests that act as carbon sinks. In addition, the production, use, and recycling of plastic products always involve emissions that must be minimized, for example, by switching to renewable energy sources. Circular economy methods need to be widely adopted. Additionally, new technologies are needed to process plastic waste for refossilization.

Despite the challenges, the carbon transfer model presents an opportunity for the plastic industry to become more sustainable. With its help, we can identify solutions that reduce the movement of carbon into the atmosphere and increase safe binding of carbon into the soil. The ValueBioMat research project is currently exploring ways to replace fossil-based plastic raw materials with bio-based alternatives and designing new material combinations and circular economy solutions. The goal is that, in the future, plastic products could form a permanent carbon reservoir.

The transition will not happen overnight, but by taking one step at a time, it is possible to transform the plastic industry from an accelerator of climate change into a carbon sink instead. With the help of research, as well as technological and business innovations, the path towards a more sustainable future is possible, and it could be possible that plastics would not be part of the problem but part of the solution.

The blogpost is written by a multidisciplinary team of ValueBioMat consortium, the affiliations of authors as follows:

a Aalto University, School of Science

b VTT, Technical Research Centre of Finland

c Aalto University, School of Chemical Engineering

d LUKE, Natural Resources Institute Finland

e University of Lapland

f Aalto University, School of Engineering