Authors: Jukka Seppälä, Laura Äkräs, Kasper Dienel / Aalto University

Plastics are central in our modern life and have plenty of good properties that advance sustainability. However, they have recently received a lot of negative and contradictory attention. But what materials are considered as plastics? This has been one of the key questions when preparing the EU single-use plastics directive. Finally, the directive (EU) 2019/904 defines plastic as follows:

‘plastic’ means a material consisting of a polymer*, to which additives or other substances may have been added, and which can function as a main structural component of final products, with the exception of natural polymers that have not been chemically modified

*as defined in point 5 of Article 3 of Regulation (EC) No 1907/2006

What can be considered as sustainable plastics?

Plastics are widely used for a reason: plastics are resource-efficient, durable, lightweight, and generate low level of emissions during their manufacturing phase. Thereby, plastics as we know them can often be considered as the most sustainable existing material solution. We have talked about the matter previously in our blogpost 17.3.2020, please check it out for more information.

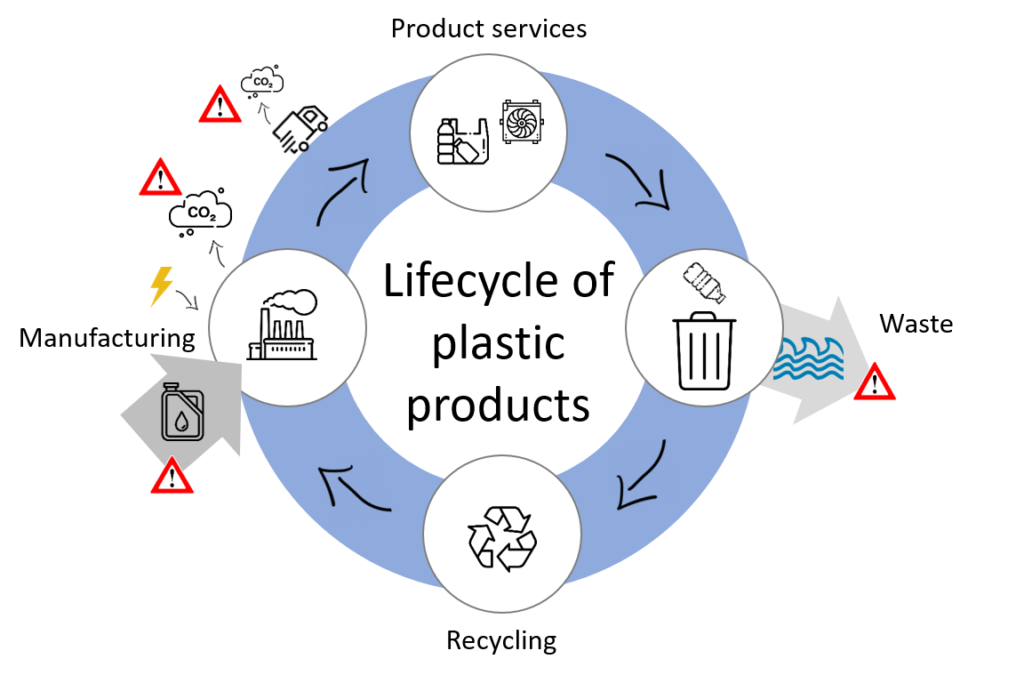

Having said this, let us rephrase the aforementioned question and ask: what plastic products can be considered more sustainable than others? This is a question that largely depends on what the intended use is. Therefore, when evaluating the most sustainable options, whether they deal with raw materials, processes, or end-of-life, they should always be assessed individually for each plastic product to assess how the product can best be implemented to be a part of a circular economy.

To simplify the sustainability discussion, let us divide it into two subtopics: first the origin and sustainability of the primary raw materials and valorization to polymers, and second, the end-of-life and circularity aspects of the plastic product. Consequently, in this blog post we will try to answer the following questions:

- How sustainable is the production of a specific plastic material?

- What happens to the plastic material after its disposal?

Even so, keep in mind that eventually we need to consider the sustainability aspects of the entire product lifetime. The use of a product with unique material properties (e.g. strength) can result in a sustainability gain over its full lifetime because of its superior performance (e.g. durability).

How sustainable is the production of a specific plastic material?

Plastics are mainly produced using fossil crude oil as raw material. To limit the use of fossil-based resources and, further, reduce carbon dioxide emissions, we need to utilize renewable resources that can be implemented in a circular economy in a larger extent. A valuable tool in assessing the sustainability of different raw materials and production processes is life cycle assessment (LCA). However, evaluation of sustainability of the full life cycle of raw materials and plastic products is not an easy task. Limitations in the existing methods and availability of reliable data make construction of reliable conclusions difficult.

In the ValueBioMat project we aim to identify and study which are the most sustainable raw materials for the production of plastics. Aalto University, in cooperation with Luke, is currently assessing the applicability and sustainability of different plant-based fats and oils for the production of plastics by analyzing parameters, such as, the chemical composition of different plant-based oils and the efficacy and sustainability of raw material cultivation and refining steps.

Additionally, within the project, we are aiming to identify methodological shortcomings in the previously reported life cycle assessments of plant-based oils to further develop these methodologies and, thereby, improve the reliability of LCA results. By using consistent LCA methodology throughout different studies, even various polymers manufactured from different raw materials can be more reliably compared. Ultimately, fair comparisons of plastics made from renewable resources to those made from petrochemical ones would be easier to conduct.

What happens to the plastic material after its disposal?

This is a loaded question as the attitude towards plastics is generally negative because of littering. Due to the material’s versatility and resource efficiency, plastics are produced in increasing quantities, while in contrast, the global infrastructure to manage the waste formed in not in place.

The durability of plastics is a problem if the product ends up in nature, but on the other hand a prerequisite for reutilizing the material. Recycling solutions provide a sustainable end-of-life option while providing renewable resources for plastics production and therefore clearly implement plastic products in a circular economy. By collecting plastics for mechanical recycling, the material can be reused a number of times before losing its characteristics. Finally, through utilization of chemical recycling, the material can be broken down into constituents and reused as feedstock for synthetizing new polymers with virgin quality.

In many cases, a plastic product that is designed to be recyclable is more sustainable than one that is difficult to recycle. For mechanical recycling, this means that products without problematic additives are preferred, while multi-layered, or composite products, and polymer blends, are challenging. On the other hand, chemical recycling technologies such as pyrolysis, will offer valuable opportunities for large scale recycling of mixed plastic streams that are difficult or technically unfeasible to recycle otherwise. Therefore, by designing products with a viable end-of-life option, by realizing effective and feasible waste management, and by using different recycling methods, the end-of-life of plastics should not be a problem.

Today, many plastic products are also replaced with biodegradable alternatives. Nevertheless, biodegradation should not be the solution for bad waste management. Counting on biodegradation can actually be counterproductive if people start relying on it. In some chosen cases, biodegradation can be applicable. However, even in these cases, biodegradation of different plastics involves uncertainty and challenges. These questions revolve especially around how effectively the plastic products actually degrade in varying environments. This however, is a topic on its own for a forthcoming blog post.

Three building blocks for sustainable plastics

As a recap and final note, here are three building blocks that can be used as an aid for creating more sustainable plastics:

1. Utilization of renewable resources as raw materials

2. Assessment of the full life cycle of plastics, including end-of-life

3. Product-specific ecodesign for implementation into a circular economy