Authors: Hannu Ilvesniemi and Frans Silvenius / Luke

Assessment of sustainability of different kinds of packaging material solution plays an important role in ValueBioMat-project. Special attention is going to be paid for possibilities and consequences to replace conventional, raw oil-based plastics with bio-based plastics.

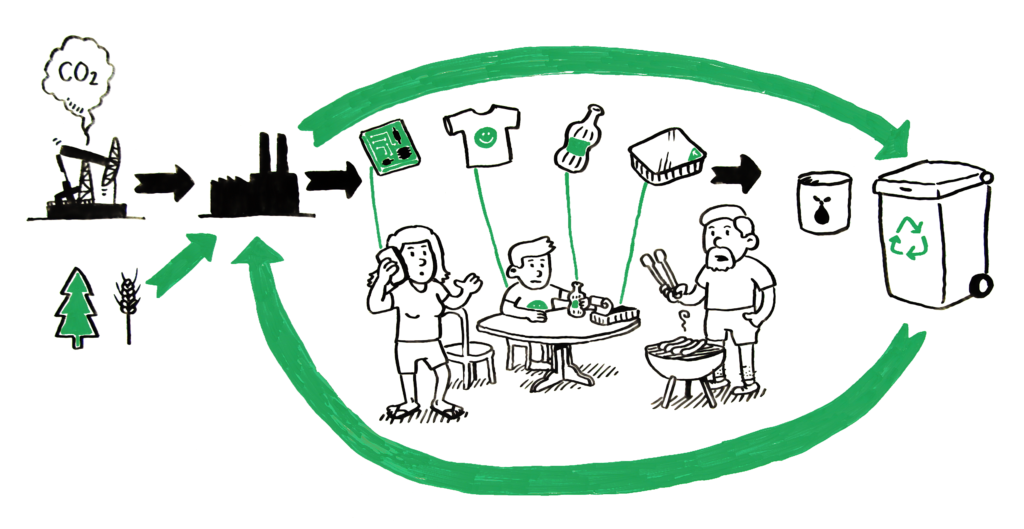

The carbon-cycle of bio-based plastics occurs mainly in natural carbon balance: the raw materials are mainly plant-based products, and the carbon content of them has been taken from atmosphere, and when they decompose, the carbon taken from atmosphere returns back. The carbon balance is different when the fossil oil-based products are dealt with, because that carbon has been taken from the ancient carbon reserves not being part of the atmospheric-vegetation carbon cycle. When fossil- based carbon is released, it increases carbon dioxide in atmosphere. There might be also other environmental benefits e.g. related to oil leakages when using bio-based plastics.

In the real world, this is not that simple.

Plant-based raw materials come from cultivation and it needs field area, fertilizers, lime and machinery work. Fertilizer inputs lead to nutrient leaches to water systems and expansion of field areas can lead to deforestation, peat degradation, destruction of high-value-ecosystems and also compete to food production and that way increase poverty. That is why sustainability research is needed for assessing the utilization potential of the new possible solutions like bio-plastics.

The sustainability consists of three pillars, which are environmental, economic and social sustainability. A comprehensive methodology to investigate environmental sustainability is life-cycle assessment (LCA), which takes into account the whole life cycle of products, production sectors and services. In this project, agriculture generated land-use and cultivation related land-use change are starting points for bio-based materials, then inputs like fertilizers and lime are included, and the technological steps of oil separation and processing, monomerization, polymerization, granulation, grinding, 3D-printing and end-of life are described and analyzed. For fossil-based products the primary production part is different, because it starts from raw oil extraction, processing and transport and goes then to monomerization.

The results of LCA can be used for guiding and supporting decision making. It is useful when making choices between two products or production systems or planning improvements of the systems or policies related to them. Also product development, business-to-business communication and marketing can use LCA as a background material. Life-cycle assessment is the widely used methodology for defining sustainability for different plastic-based solutions and the results carried out in this project will be presented and communicated when they will be completed in 2021-2022.